In the realm of utility locating and excavation, accuracy is paramount. One of the most critical steps in this process is verifying the location of underground utilities before construction or excavation activities commence. Traditional excavation methods often pose risks of damage to existing infrastructure, leading to costly and potentially hazardous incidents. However, vacuum excavation for verification offers a non-destructive and highly precise solution to this challenge. By safely exposing underground utilities with high-pressure air or water, vacuum excavation allows workers to visually confirm their location with accuracy and confidence. Furthermore, it aligns with the principles of Subsurface Utility Engineering (SUE) Quality Level A (QL-A), ensuring the highest level of accuracy and reliability in utility locating practices.

Non-Destructive Method

In my view, vacuum excavation should be an integral part of any comprehensive utility locate strategy. Unlike traditional methods such as mechanical digging, which carry a high risk of accidentally striking and damaging buried utilities, vacuum excavation offers a far safer alternative. By using high-pressure air or water to safely expose underground utilities, vacuum excavation reduces the risk of damage. This non-destructive method is especially critical in urban environments, where utilities are densely packed, and the margin for error is virtually nonexistent. By minimizing the potential for damage, vacuum excavation not only protects the integrity of existing utility networks but also prevents service disruptions that can inconvenience entire communities.

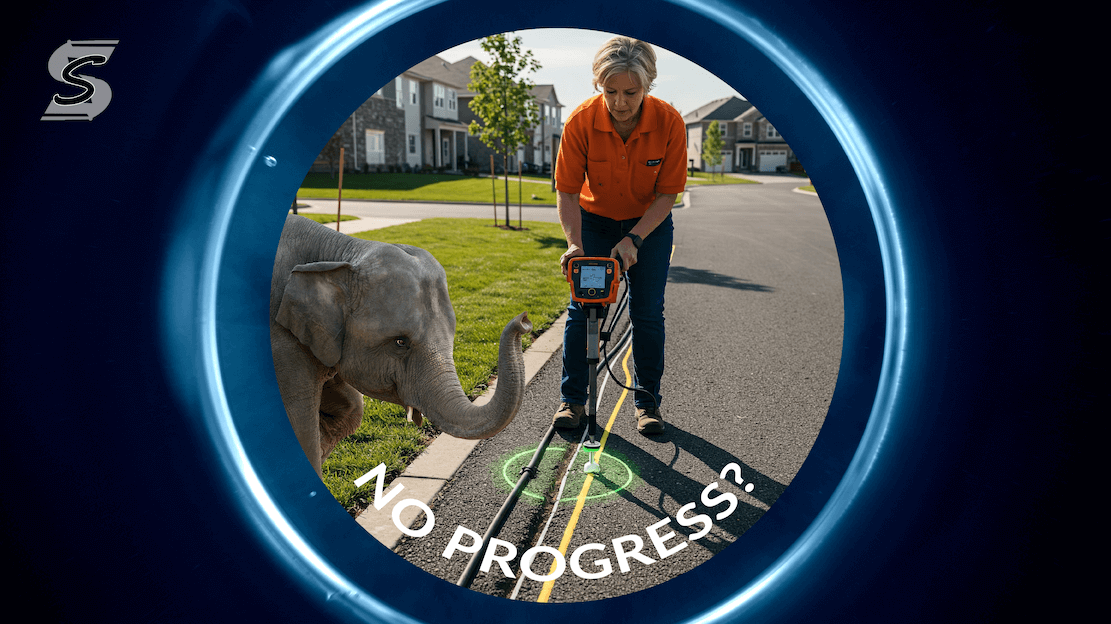

Accuracy

The accuracy provided by vacuum excavation is simply unmatched. It gives us clear, precise visibility of underground utilities, allowing workers to verify their location with unparalleled confidence. This level of precision is crucial in preventing accidental damage during construction or excavation activities. When workers can visually confirm the exact position of utilities, they can ensure that any proposed boring paths or construction activities steer clear of existing infrastructure. This precise identification is essential for avoiding costly delays and keeping project timelines on track. For any project requiring exact utility location data, vacuum excavation should be the method of choice.

Reduced Risk

The risk reduction benefits of vacuum excavation cannot be overstated. By accurately locating underground utilities before construction begins, we can significantly reduce the likelihood of cross bores, utility strikes, and the associated safety hazards. Avoiding these incidents not only prevents costly and dangerous situations, such as gas leaks, water main breaks, or electrical outages, but also enhances overall safety on construction sites. By proactively identifying and avoiding conflicts with existing utilities, vacuum excavation protects both the workforce and the public from the dangers associated with utility damage.

Efficiency

From an efficiency standpoint, vacuum excavation is a game-changer. This method allows workers to quickly and precisely expose buried infrastructure, reducing the time and labor required for inspection and verification tasks. This efficiency translates into significant cost savings for utility companies and construction projects. By minimizing downtime and delays associated with inaccurate utility locates, vacuum excavation enables projects to proceed with confidence and without unnecessary interruptions. The speed and accuracy of this method make it a highly cost-effective solution, ensuring that projects stay on schedule and within budget.

The Future: Integrating SUE QL-A Data with AR Technology

As technology continues to advance, the integration of SUE QL-A data with augmented reality (AR) represents a significant leap forward in utility management. AR can overlay precise utility location data onto real-world views, allowing workers to see the exact positions of underground utilities in real-time through devices such as smart glasses or tablets. This integration enhances situational awareness and decision-making on construction sites, further reducing the risk of utility strikes and improving overall project efficiency.

However, the accuracy of AR overlays is only as good as the data they are based on. Without the primary source data that hydrovac offers, there is a significant risk of discrepancies. AR systems relying on less precise methods of utility location may present inaccurate information, leading to potential hazards and inefficiencies. Therefore, the high confidence and accuracy provided by SUE QL-A via vacuum excavation are indispensable for the successful implementation of AR technology in utility management.

Conclusion

Vacuum excavation, as part of the SUE QL-A process, sets the standard for accuracy, safety, and efficiency in utility locating. Its non-destructive nature, precise identification capabilities, risk reduction, efficiency, and environmental benefits make it an unparalleled method in the field. As we move towards integrating advanced technologies like AR into utility management, the high-quality data provided by vacuum excavation will be crucial in ensuring these innovations are both effective and reliable.

Incorporating SUE QL-A data into AR systems will revolutionize the way we manage and interact with underground utilities, but only if the foundational data is accurate. Therefore, investing in and prioritizing vacuum excavation for utility verification is not just a best practice; it is an essential step towards a safer, more efficient, and technologically advanced future in utility management.

Share this Post